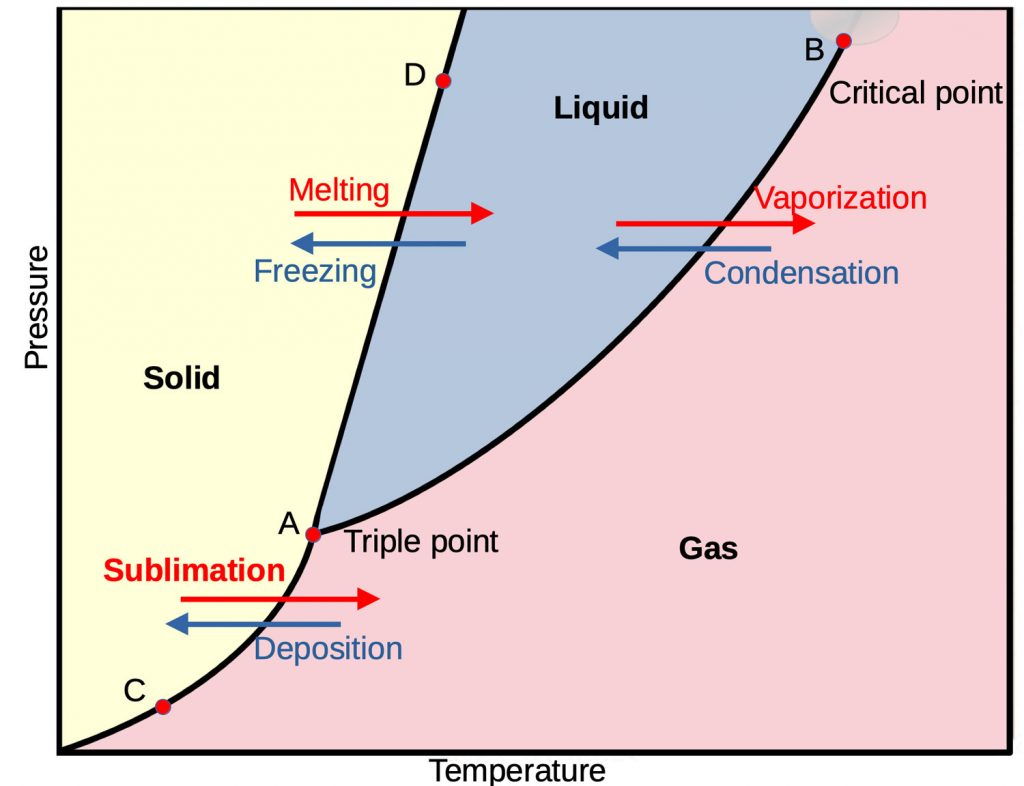

Basically you put frozen products to a chamber containing very cold condensing plates (-50°C in our case or lower for special medical cases). Then you suck up all the air which corresponds to the air pressure 200 km above your head.

This starts sublimation where water is transferred from the product to the condensers. In the second phase we heat the product up to 30°C to get rid of the rest of the moisture.

You can freeze dry all food products. The result is authentic flavor and nutrients of your favorite fresh food, preserved with absolutely no additives and with a sustainable, efficient method. It turns fresh food into healthy instant snacks or if you prefer, placing them in water turns them back to fresh. Just the way they were before they were dried.

All this applies to fresh raw food and cooking equally well. Fresh salad is just as fresh and crispy as it originally was, dry meat can be rehydrated and cooked into a juicy rare steak and gravlax is still gravlax, with no heat-induced discoloration.

Freeze drying applies to medical material, too, and even to wet documents.

How did we come to this?

Jacques-Arsene d’Arsonval invented freeze drying already 1906 in College de France in Paris. WW2 blood plasma was transported freeze dried from USA to Europe. Nescafé Gold®, 1965, was the first real commercial application of this technology.

All current freeze dryer vendors use basically same technology from 1960s. We have stepped to 2020s and we will continue to develop it further.